The release of the new general catalogue of technical foams fulfils two very important purposes. On the one hand, it reflects the work, progress and knowledge built up by ZFoam over the last few years. And on the other, it showcases the growing range of opportunities that we make available to you both in terms of materials and their possibilities for transformation.

This is essential to allow you to innovate and improve your products.

Find out about our processes for transforming technical foams

Throughout the year we’ve been presenting the new catalogue and showing you all our new products and describing its sections devoted to Azote foams, our reticulated and non-reticulated polyolefin foams, our ECO and BIO foams and other types of foams and insulating materials.. We now end our overview by focusing on the last section, which is dedicated to the transformation processes for technical foams.

We summarise the processes that ZFoam offers:

- Engraved and textured foams: these come in different types, such as ribbing, deep engraving and fine engraving. We can also replicate custom designs.. Depending on their application, the resistance of foams to slipping and abrasion can be improved, and their ability to absorb impacts can be enhanced, among other characteristics.

- Lamination: we offer a wide variety of products laminated with polyethylene (PE) and polyurethane (PU) sheet, aluminium foil, paper, non-woven fabric, raffia, cardboard and plastic, as well as all sorts of self-adhesive coatings. Among the properties that lamination gives to foams are resistance to moisture, light and UV radiation, in addition to tearing, abrasion, compression and flame, depending on the material.

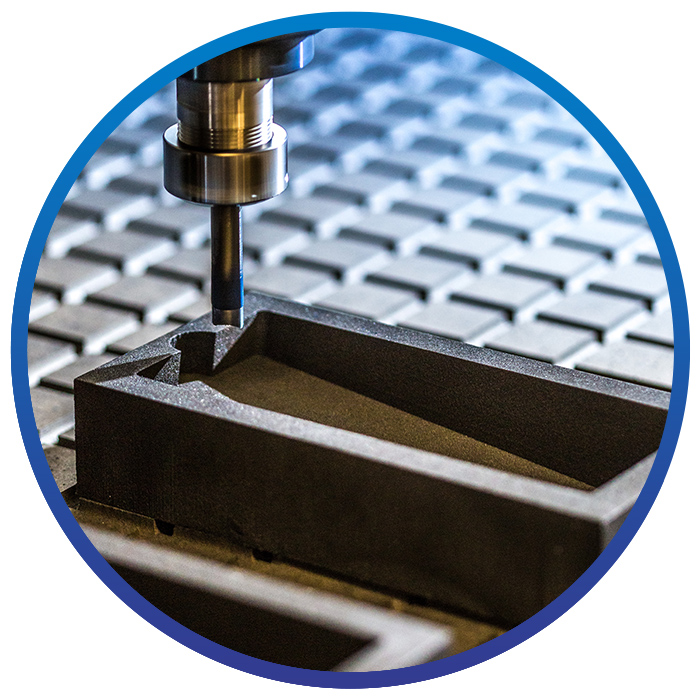

- We also include printing, cutting and perforation, CNC machining, adhesive coating, laser marking, thermoforming and many other options for the greatest possible customisation of your foam solutions, as well as adapting them to your needs.

In addition to the properties each transformation process brings, it should be highlighted that practically all of them help to increase the resistance of the foam and even improve its appearance in aesthetic terms. This is of great importance depending on the end product to which each specific material will be destined (for example, almost every sport product or packaging solution).

We know that we’ve spoken about a large number of transformation processes and that each of them has a different purpose and performance, which is why our technical team is at your service to provide the detailed information you require and to answer any queries that you may have at no obligation to you.

This post completes our series of articles on our new general catalogue of technical foams, through which we hope to have offered you a clear picture of its content and the advantages that our products offer your business.

We remind you that you can download it here in PDF, and that if you would like to receive it in hard copy with real samples of its 80 materials, you need only let us know.

We are very proud of our accomplishment.