Reticulated PE foams

Chemically expanded reticulated polyolefin and polyethylene foams.

The polyethylene foams we convert are widely used for their outstanding quality and the range of applications and uses they offer. Some of the most common include the presentation and protection of all kinds of different products, the production of packaging and packing materials, and the manufacture of products for the sports industry and the industrial and construction sectors.

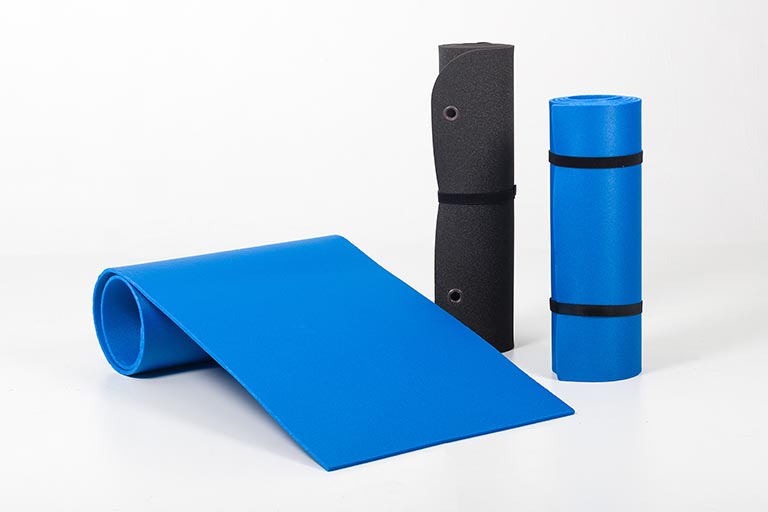

Presentation formats for reticulated PE foam:

- Sheets

- Spools

- Finished items

RETICULATED PE FOAMS FOR:

Automotive industry

Rail industry

White goods

Logistics

Electronics

Healthcare industry

Footwear

Food industry

Presentation packaging

Suitcases

Artworks

Tools

Sample cases

Logistics

Isothermal containers

Electronics

Mats

Swimming pools

Tatami flooring

Archery

Padel racquets

Renewable energies

Energías renovables

Reticulated polyethylene foams

We are specifically referring to the process in which a physical or chemical reaction between chains of polymers – which is designed to bond the polymers – enables us to create a foam that is extremely impermeable and flexible, with excellent insulating capacities and improved mechanical properties as well as highly homogeneous cells and exceptional durability.

This makes the foams particularly suitable for use as thermal insulators or to provide protection against impacts, among other applications.

Reticulated PE foams: density and base

Our reticulated PE foams come in densities ranging from 25 to 250 kg/m³

with variants based on LDPE (low-density polyethylene), HDPE (high-density polyethylene) and EVA (ethylene-vinyl acetate).