Azote Foams

Reticulated polyolefin foams boast outstanding levels of purity and are manufactured using a unique high-pressure nitrogen injection technique.

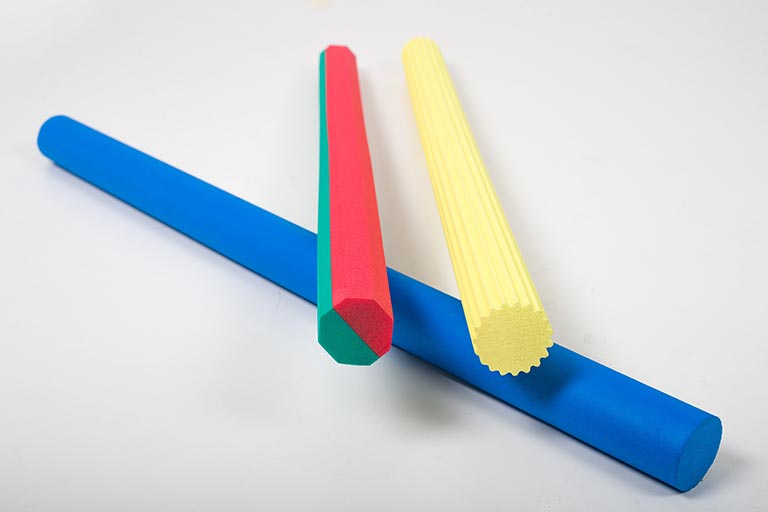

The range of Azote foams includes PLASTAZOTE® (with an LDPE/HDPE/metallocene base), EVAZOTE® (with an EVA copolymer base offering greater flexibility than PLASTAZOTE®) and SUPAZOTE® (very soft and light). These reticulated polyolefin foams boast outstanding levels of purity and are manufactured using a unique high-pressure nitrogen injection technique.

They are characterised by the absence of chemical residues from the foaming process, volatile organic compounds (VOCs), CFCs and HCFCs. Special grades with flame-retardant additives (grades FR and FM) are also available, along with anti-static and conductive products (grades SD and CN).

Presentation formats for Azote foams:

- Sheets

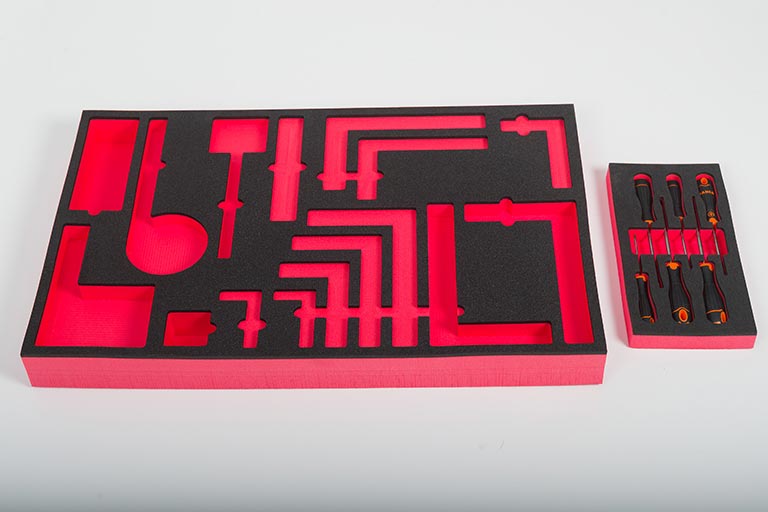

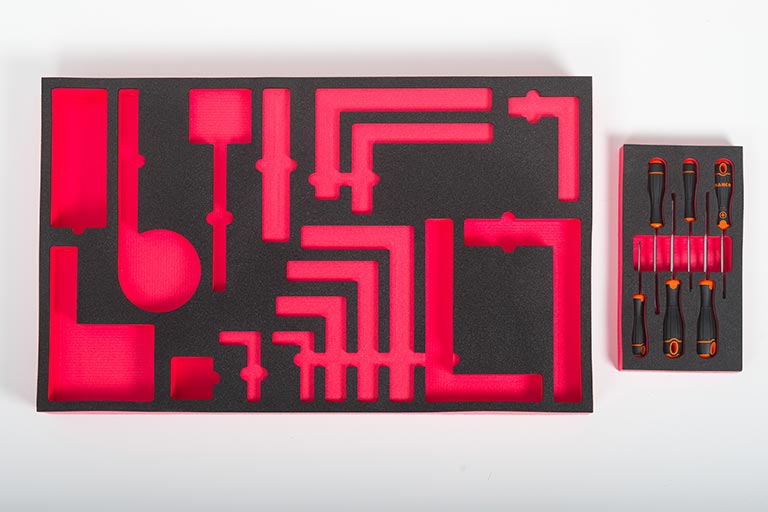

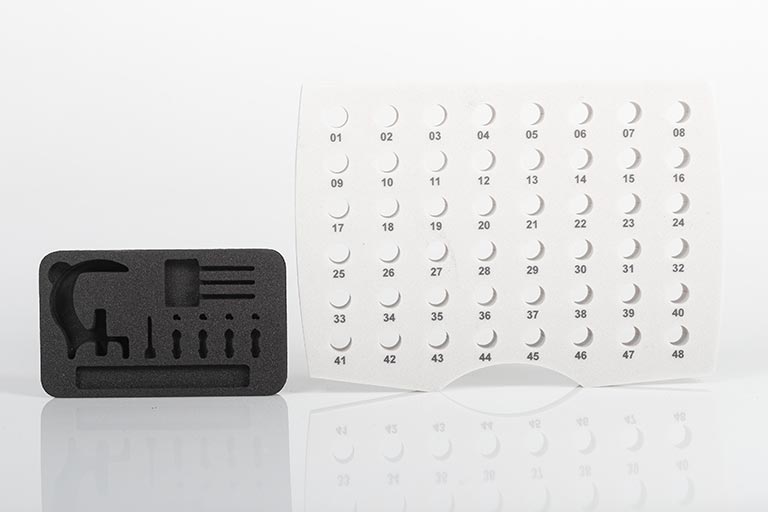

- Finished items

Azote foams for:

Automotive industry

Rail industry

White goods

Aeronautical industry

Shipbuilding industry

Electronics

Healthcare industry

Footwear

Food industry

Renewable energies

Presentation

Suitcases

Artworks

Tools

Sample cases

Isothermal containers

Electronics

Mats

Swimming pools

Tatami flooring

Body Board

Padel racquets

Building

These foams boast the following properties:

- They allow permanent contact with human skin.

- They impede the retention of liquids and moisture.

- They are non-toxic, latex-free, reusable, hypoallergenic, and transparent for the purposes of MRI and CT scans and X-rays.

- These types of foam are available in many different grades, ranging from the lightest (LD15, LD24 and EV30) to the most rigid (HD30, LD70 and PK80).

Applications of Azote foams

Owing to their exceptional properties, Azote foams have a very wide range of applications: for example, they are used in the manufacture of sports, orthopaedic and medical equipment, as well as in the electronics, automotive and aviation industries and in the production of white goods.