As manufacturers of foam solutions for all types of applications and sectors, at ZFoam we are able to fully adapt each product to your needs and those of the target users.

In addition to studying the characteristics, applications and degree of sustainability of each material, we must highlight a very important aspect that you are very interested in taking care of, especially in the packaging sector: foam grip on the product.

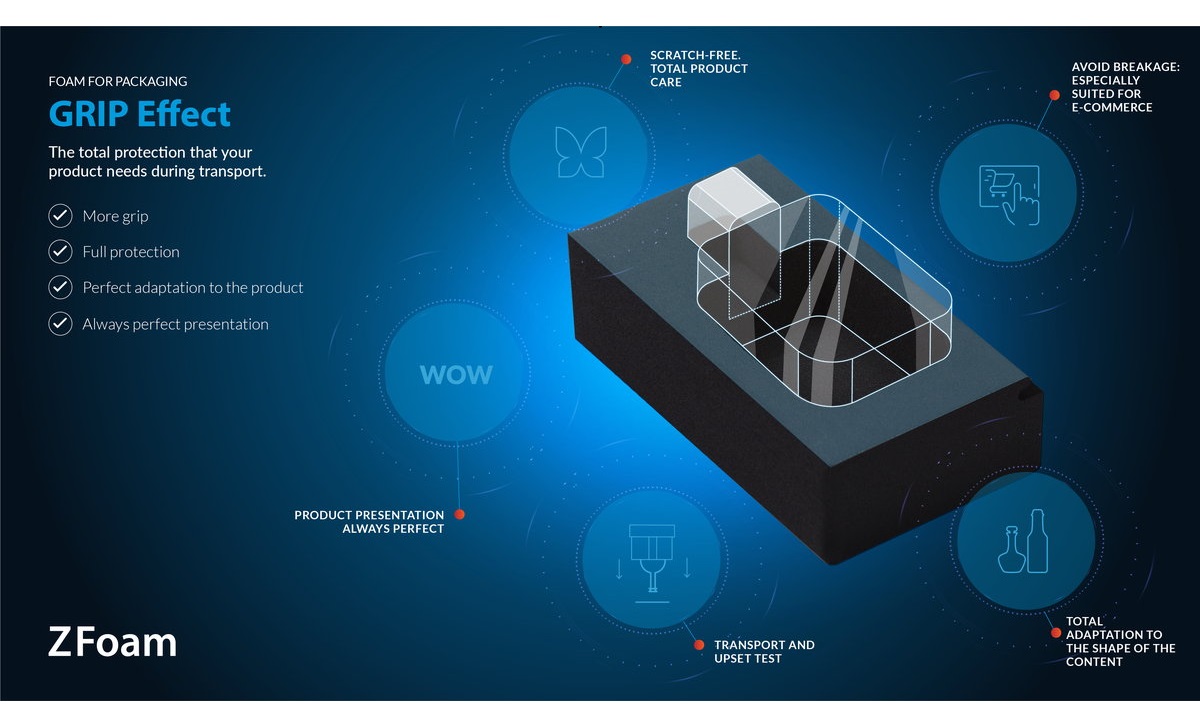

ZFoam Grip Effect, foams with maximum grip

This characteristic allows the foam to keep the product perfectly positioned and secured in its box, preventing it from turning, moving, falling over or, in the worst case, breaking. In addition, as it is a very soft material, you will get maximum grip without scratching, damaging the product at any time.

It must be said that, among the materials that can be used to achieve this, foam performs better than others. A characteristic that we can control even more by working with EVA foam (ethylene vinyl acetate), as well as the hardness or the size of the cells of this material.

It must be taken into account that in addition to fulfilling an important aesthetic function, the foam insert allows it to successfully pass the transport and roll over tests. To give an example, in these tests, the product is placed upside down and must be held correctly for between 5 and 30 seconds, something that is rarely achieved if it is not using some type of foam, like the ones we usually work with at ZFoam.

A recyclable, sustainable and perfect material for ecommerce

At a time when online purchases and transport of products have grown exponentially, it is even more necessary to use materials with this grip or good grip of the product and guarantee that it will arrive in perfect condition to final destination or end customer. In fact,, the breakage rate of products using our foam inserts is almost zero..

Its use protects and holds cosmetic products or wine bottles, to give a couple of examples.

To these advantages that we have described we must add the low environmental impact derived from the use of our foams, since:

- Very small amounts of raw material are necessary for the manufacture of the inserts.

- Whenever possible, we use our ecological ECO & BIO foams. This range is made with recycled or plant-based materials which, on many occasions, have a negative carbon footprint.

- All foams can be recycled by simply placing them in the yellow bin at the end of their useful life.

Finally, we remind you that at ZFoam we maintain a firm commitment to innovation, sustainability and respect for the environment, which is why we invite you to discover our Life Cycle Assessment. Thanks to it, you will be able to know exactly the environmental impact derived from the use of our products, and even compare it with other materials.