The battery is the new backbone of electric vehicles, and within it, foams play a discreet but decisive role. They seal, insulate, support and dissipate heat. But would you know how to choose the right foam to avoid unexpected costs, delays or approval issues?

Regulatory context in Spain

The UNE 0062 standard and PERTE VEC II subsidies require proof of passive safety and traceability of polymeric materials used in electric vehicles manufactured in Spain. Selecting foams that meet these requirements avoids last-minute redesigns and speeds up the process of obtaining subsidies.

1 Set the goal before the technical data sheet

A foam is selected when engineering, quality control and purchasing share the same priority. Before opening a technical data sheet, the risk to be avoided and the expected benefit must be put on the table

- The risk to be neutralised: cell-to-cell heat propagation, vibrations that loosen joints, electrolyte infiltration, etc.

- The advantage to be achieved: lighten 8 kg to gain autonomy, reduce time to validation or add ESG points…

If the most feared scenario is a thermal leak in < 90 s, the priority will be a BISCO® UL 94 V 0 silicone capable of withstanding 200 °C. If weight is the main issue, moulded EPP is the natural choice.

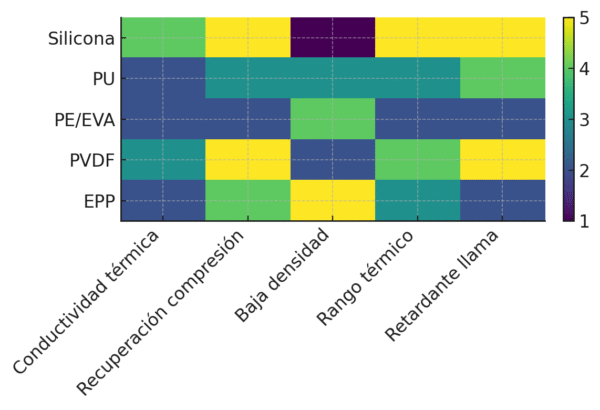

Quick visual overview

As tables can be confusing, it is best to refer to the following heat map, which summarises at a glance which foam dominates in each property:

*Express glossary:

Compression set (permanent deformation) = loss of thickness after compression and ageing.

Closed-cell = structure impermeable to water and gases.

3 The ‘character’ of each family

Each technical foam has unique properties that make it ideal for certain scenarios and less suitable for others. This brief description will help you quickly recognise which one best suits your specific application

| Family | Strengths | Weaknesses | Typical application |

|---|---|---|---|

| Silicone

(BISCO® HT-800, PORON® EVExtend) |

Withstands temperatures from -60 °C to +200 °C, UL 94 V-0, compression set < 5%, semi-closed microcell, good resistance to glycol-water refrigerants. | High density and cost. | Gap-filler heat sink under 4680 cells |

| Polyurethane (PU)

(ZF-EV 45-120 kg/m³ formulations) |

Flexible, easy to cut, moderate cost, acceptable chemical resistance to refrigerants. | Ageing > 110 °C; flammable without additives. | Battery cover seals. |

| Polyethylene/EVA

(EVA copolymers for high resilience) |

Very lightweight, closed cell, good dielectric, water absorption < 1%. | UL 94 HB; compression set > 12%. | Cushion pads between pouch cells. |

| PVDF

(Solef® cross-linked PVDF) |

Inert to electrolyte carbonates, UL 94 V-0, high dielectric strengh. | Expensive, medium-high density. | Seals on cold plates with electrolyte contact. |

| EPP | Ultra-lightweight, shock-absorbing, 3-D moulded. | Thermal limit 110 °C; UL 94 HB. | Structural spacers in cylindrical modules. |

* Quick note on closed cells

The PE/EVA and BISCO® silicone families have a closed-cell structure, limiting liquid absorption and increasing dimensional stability.

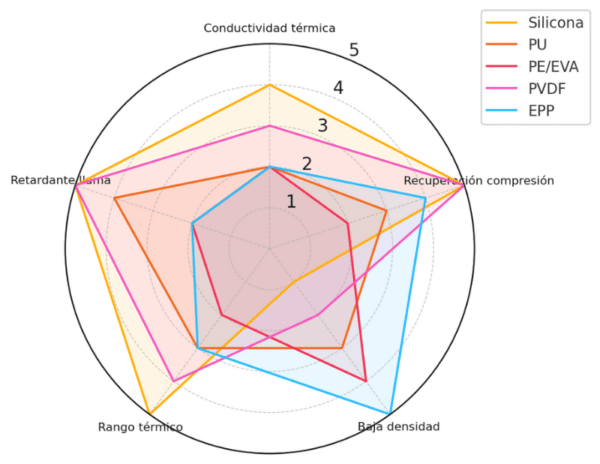

4 360° view of performance

To see at a glance the balance between conductivity, deformation, density, temperature range and fire behaviour:

5 Step-by-step methodology

Choosing a foam is easier if you follow a structured process. Here are five practical steps to choose the most suitable material for your application scenario and specific requirements.

- Failure scenario. Identifying the most critical threat (e.g., thermal propagation).

- Weigh criteria (1-5) according to impact on safety and warranty cost.

| Criterion | Weight (pouch module) |

|---|---|

| Fire safety UL 94 | 5 |

| Thermal conductivity | 4 |

| Chemical resistance | 3 |

| Cost €/m² | 2 |

| NVH (noise and vibration) | 1 |

- Filtering standards. If the pack specification requires UL 94 V-0, discard all HB families from the outset, thus saving days of development.

- Prototype and validate in a controlled environment

- Thermal cycle –40 / +85 °C, 96 h at 50% compression.

- Chemical test 72 hours immersion in electrolyte (EC + DEC) at 60 °C.

- Align areas. Select the foam that best reduces the relative risk.

Reducing the module temperature by 5 °C extends the service life of the cells by ≈ 10%, reducing incidents.

6 Good integration practices

The final effectiveness of the foam also depends on how it is integrated into the battery pack. Below are some practical recommendations for optimising this integration in production.

- Low VOC adhesive: acrylic laminate <5 g VOC/m².

- Zero gaps tolerance: joints ≤ 0.2 mm to prevent rattling and leaks.

- Fluid TIM + silicone: ideal duo with cold plate.

- Residual compression tests: ≥ 60% after 100 lid opening cycles.

The final performance of the foam depends as much on its formulation as on how it is incorporated into the pack. Going beyond the basic tips, this table provides some guidelines:

| Step | ZFoam Recommendation | Benefit |

|---|---|---|

| Cleaning and conditioning | Isopropanol 70% + degassed for 30 minutes at 50°C in machined aluminium. | Constant adhesion; no delamination. |

| Adhesive | Acrylic PSA < 5 g VOC m² for REACH projects; hot-melt PUR if you need ≥ 2 N cm⁻¹ at 85 °C. | Quick installation without compromising peelability. |

| Joint design | Target compression: 30-40% in silicone, 45-50% in EPP; radii ≥ 1 mm in corners. | Maintains IP-67 and prevents buckling. |

| Zero gap control | Optical verification of critical thicknesses ≤ 0.2 mm; EVA wedges in gaps. | Eliminates dust/water entry points |

| Thermal compatibility | Conductive silicone (Shore 00 30-45) + TIM fluid on cold plate. | ΔT edge-cell ↓ ≥ 3 °C compared to TIM alone. |

| Residual compression | Target ≥ 60% after 100 lid opening cycles. | Guarantees sealing throughout service life. |

*Quick rule

For packs subjected to harmonic vibration > 12 g, design the foam to work at 35% of its original thickness, so that it absorbs energy without premature fatigue.

The foam that determines the result

Choosing the right foam is no small matter. Ultimately, it all comes down to finding the right balance between safety, cost and sustainability:

- Extreme safety — BISCO® / PORON® silicone, PVDF®, Zotek N®, Zotek F®.

- Cost & acoustics — PU, Azote®

- Structural lightness — moulded EPP.

Can we help you make that decision? Contact us.