What is ESD?

ESD (Electrostatic Discharge) is the phenomenon of sudden release of static electricity accumulated between two objects with different electrical potentials. This discharge can cause damage to sensitive electronic components and other delicate devices, making ESD protection crucial in a number of industries.

Packaging for electrostatic discharge (ESD)-sensitive devices

The design of such packaging requires consideration of the physical requirements of the packaging material as well as its electrical properties. In this article, information is detailed on:

- General classifications used for ESD materials.

- ZFoam range of ESD foams

- Standards commonly used to characterise such materials.

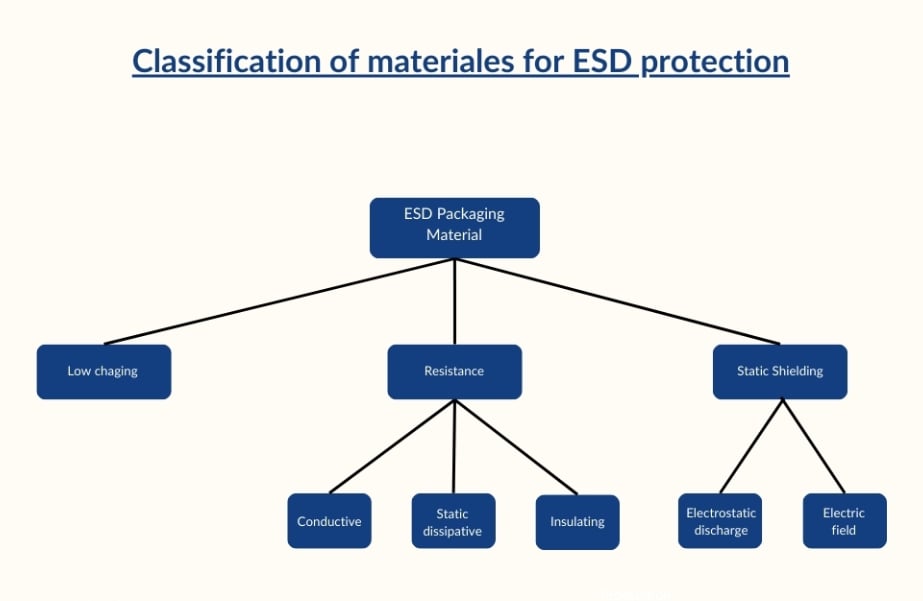

Classification of ESD Materials

Materials for packaging ESD sensitive devices can be divided into three classes according to their electrical properties. The material classification shown in Figure 1 is based on the definitions in ANSI/ESD S541-2003:

-

First Class: “Low Charging” materials ,: These materials are designed to reduce charge accumulation by triboelectrification, i.e. charge produced by contact and separation of materials.

-

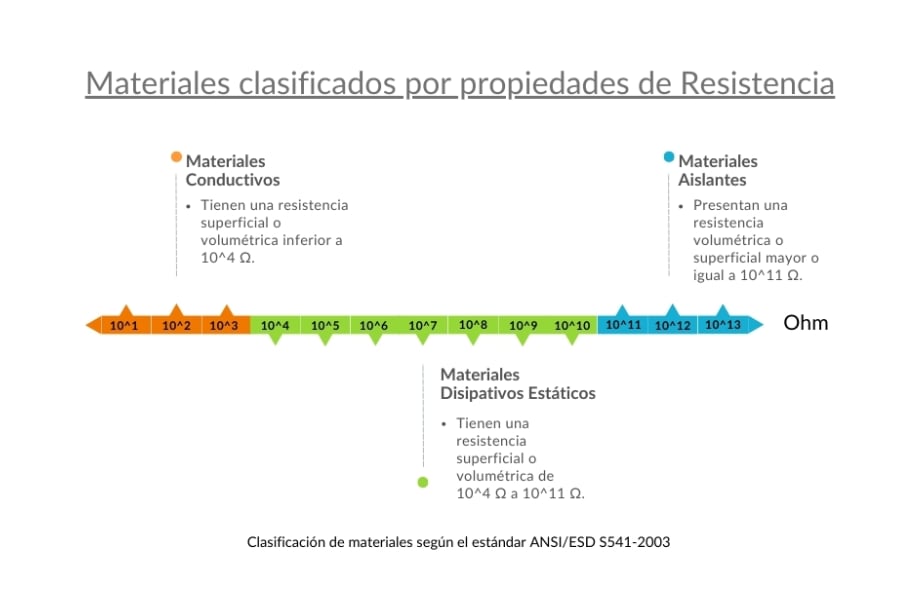

Second Class: Materials classified by strength properties. The ranges for each of the properties vary between different standards and the values listed below are taken from ANSI/ESD S541-2003:

- Conductive Materials: Have a surface or volumetric resistance of less than 10^4 Ω.

- Static Dissipative Materials: Have a surface or volumetric resistance of 10^4 Ω to 10^11 Ω.

- Insulating Materials: Have a volumetric or surface resistance greater than or equal to 10^11 Ω.

-

Third Class: Static Shielding.

- Electrostatic Discharge ,: Materials capable of attenuating an electrostatic discharge when formed in a closed container.

- Electric Field,:Materials that protect sensitive devices from the effects of electric fields.

For a more in-depth analysis of antistatic, static dissipative and conductive foams, and to understand why they are becoming more and more important, we invite you to read our article: Antistatic (AS), Static Dissipative (ESD) and Conductive (CN) Foams: What are they and why are they becoming more and more important.

Resistance and Resistivity

The electrical properties of a material can be expressed as resistance or resistivity. If the general test design is known, a resistance value can be converted to equivalent resistivity by simple multiplication. The definitions below are taken from ASTM D 257- 1993.

- Surface Resistance: Ratio of the direct current voltage applied to two electrodes at the surface to the current between them. The unit of surface resistance is Ω.

- Surface Resistivity: Surface resistance of the material multiplied by the ratio of the surface dimensions of the sample (width of the electrodes defining the current path divided by the distance between electrodes). The unit of surface resistivity is Ω/sq.

- Volumetric resistance: Ratio between the DC voltage applied to two electrodes (on or within a sample) and the current in the sample volume between the electrodes. The unit of volumetric resistance is Ω.

- Volumetric Resistivity: Volumetric resistance of the material multiplied by the ratio of the volumetric dimensions of the sample which transforms the measured resistance into the resistance obtained if the electrodes had formed opposite sides of a unit cube. The unit of volumetric resistivity is Ω.cm (sometimes written as Ω-cm).

Test Methods for ESD materials and foams.

There are several standards for measuring the resistance and resistivity of ESD protection materials. Over the years, some test methods have proven to be less reliable than others, and the process of identifying a suitable measurement for each type of application is still ongoing.

- Surface Resistance: For surface resistance measurements of static dissipative flat materials, such as foam sheets, ESD STM 11.11-2001 is widely used. This standard is also mentioned in ANSI/ESD S541-2003. IEC 61340-5-1 describes an identical test method for the measurement of surface resistance and surface resistivity.

- Volumetric Resistivity: The measurement of volumetric resistivity of foams is often performed according to ASTM D991-89 (re-approved in 2014). This standard describes a test method for rubber products but has been found suitable for the measurement of other flat packaging materials. The standard is also mentioned in the JEDEC standard JESD625-A.

A standard for low-load materials has not yet been developed, but guidance for understanding the triboelectric phenomenon and the test methods currently used for triboelectric load testing in static control for electronics can be found in ESD ADV 11.2.

ZFoam’s ESD Foam Range

Static Dissipative Foams:

Azote range: Plastazote® LD30SD and Plastazote® LD40SD.

Black coloured materials available in sheet form in different thicknesses, expanded by a unique nitrogen expansion process. Free of CFC (chlorofluorocarbons), HCFC (hydrochlorofluorocarbons) blowing agents and chemical foaming residues. They share typical characteristics of our standard foams, such as a closed cell structure, isotropic physical properties, good performance as a cushioning material and good chemical resistance. These products are also thermoformable.

The formulation used to produce Plastazote® LD30SD and Plastazote® LD40SD overcomes the problems typically associated with producing a polyethylene foam suitable for ESD-sensitive equipment packaging.

General approaches to the modification of polyethylene foams include surface treatment with chemicals, chemical additives such as amides or amines and conductive additives.

- Surface treatment with salt solutions: Adds cost to the converter and is often unreliable, as it can rub off or wash off and requires high humidity to work effectively.

- Chemical additives such as amines: Depends on the migration of the additive to the surface of the material. Although this method tends to provide a longer lasting effect than surface treatment, leaching of some additives can cause deterioration of the electronic equipment that the foam is intended to protect and an increase in surface resistivity due to loss of the additive. This method also requires high humidity to give satisfactory performance, as the additives are activated by moisture.

- Conductive additives such as carbon black: These can be used to create permanent low resistivity. However, formulating materials in the static dissipative range has proven difficult, as the materials tend to be either conductive or insulating. This is due to the properties of carbon black, which requires specific concentrations to create a conductive material.

As a result of extensive development, Plastazote® LD30SD and Plastazote® LD40SD materials are manufactured with a controlled process to provide a truly static dissipative nitrogen expanded cross-linked polyethylene foam.

PNR range: PNR 30 AS and PNR 35 AS

Pink coloured materials manufactured using amine-based additives that provide this characteristic colour. As mentioned above, these additives are activated by humidity and, therefore, variations in surface resistivity related to the climate or working environment must be considered.

LJ range: LJ 33 FR AS

Special material including antistatic and flame retardant (FR) additives. The activation of the antistatic additives, as in the previous case, is caused by ambient humidity.

PUD range: PUD AS

Open cell polyurethane foam type (not closed cell like polyethylene foams). Pink colour and additive activated by ambient humidity.

Conductive foams:

AZOTE range: Plastazote® LD32 CN, Plastazote® LD50 CN and Evazote® EV45CN.

Black coloured materials available in sheet form in different thicknesses.

They have the same purity properties and unique characteristics due to their manufacture with nitrogen as the blowing agent and are thermoformable.

The formulation is made with a special carbon black additive to provide conductive properties. The additive is introduced by pre-compounding (no subsequent impregnation as in some types of conductive foams) and is completely encapsulated in the polymer. Therefore, the foams do not generate particulates and do not leave marks.

Compliance with ESD protection standards

Definitions of conductive foams vary slightly between different standards. Below is a summary of the standards related to ESD protection in packaging:

General Standards:

- ANSI/ESD S541-2003: Material with a surface resistance less than 10^4 Ω or volumetric resistance less than 10^4 Ω.

- ANSI/ESD STM 11.12: Material with a volumetric strength of less than 10^4 Ω.

- ASTM D991-89 (2014): Material with a volumetric resistivity less than 10^4 Ω.cm.

- JESD625-A (1999): Material with a surface resistivity less than 10^5 Ω/sq or volumetric resistivity less than 10^4 Ω.cm

Military Standards:

- DStan 81-146/1: Material with a volumetric resistivity of 10^2 to 10^5 Ω.cm.

- MIL-HDBK-263B: Material with a volumetric resistivity less than 10^4 Ω.cm or surface resistivity less than 10^5 Ω/sq. This standard contains other physical property requirements that must be verified before selecting a suitable material for applications requiring compliance.

Conclusion

ESD foams are essential for the protection of electrostatic discharge sensitive devices.

ZFoam’s product range offers reliable and effective solutions for various industrial applications in compliance with the most stringent international and military standards, ensuring the quality and safety of our products.

For more information about our products, and how they can benefit your business, we invite you to contact us and see together how to improve the competitiveness of your project.