Can industrial packaging protect your most delicate equipment while reducing your environmental footprint?

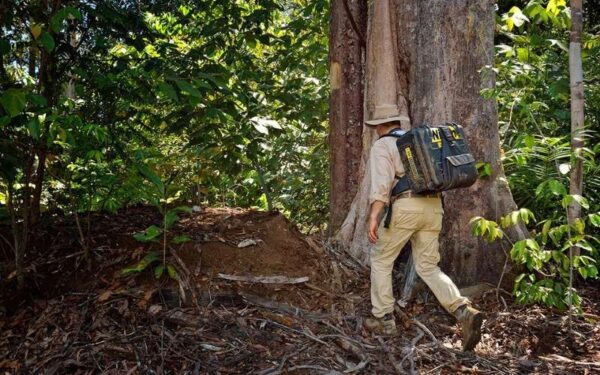

At ZFoam we believe it can, and we make it happen. We combine the legendary robustness of Explorer Cases with our eco-friendly technical foams to create packaging solutions that protect your contents, your brand’s reputation… and the planet.

Certified high-performance protection

Explorer Cases are manufactured from Prolene HCR-280 polypropylene copolymer with an exclusive formulation and undergo the same tests as military containers:

- IP67: total dust and water resistance (72 hours submerged at 1.5 metres).

- STANAG 4280 & DEF STAN 81-41: impact, vibration, and free fall resistance.

- Temperature range −33 °C / +90 °C: operational in scorching deserts or on Arctic platforms.

The interior is designed down to the micrometre. CNC milling, 3-axis waterjet cutting and thermoforming allow us to accommodate everything from a laser head to a surgical instrument kit.

Data that matters

| Feature | Typical value |

|---|---|

| Compression resistance | >120 kg/cm² |

| Shock absorption (g-peak) | ≤ 30 g |

| Maximum buoyancy | up to 120 kg in #10840 models |

Sustainability as standard

Having the most resistant case on the market is no longer enough; the industry demands certified environmental responsibility:

- ISO 14001: annually audited environmental management system.

- ISCC PLUS: traceability of circular and bio-recycled raw materials. Foams with 40% bio-recycled content (e.g. used vegetable oils).

- Clean-tech foaming: we use atmospheric nitrogen, without CFCs, HCFCs or VOCs.

This translates into recyclable, odourless foams with no chemical residues, ideal for sectors where purity is critical (medical, food, precision optics). Find out more about our green commitment in the article ECO and BIO foams in the new ZFoam catalogue.

From waste to resources

We use production leftovers to make agglomerated sheets for tatami flooring or cushioning layers, closing the loop.

More than just a filler

We select the exact density, hardness, and cell structure for each application:

| ZFoam family | Density (kg/m³) | Main advantage | Featured application |

|---|---|---|---|

| Azote® | 25-70 | Ultra-lightweight | Industrial drones |

| Zotek® F | 30-75 | Flame retardant (FAR 25.853) | Aviation |

| Cross-linked PE | 45-100 | Cost/performance | 4.0 Logistics |

| Filtering PU | 18-30 | Controlled permeability | Medical instruments |

We process each block in 2D and 3D without overcutting, reducing waste by up to 15%.

Why choose Explorer Cases by ZFoam?

- Comprehensive protection: military standards without excessive weight.

- Total customisation: custom foam engineering, laser serialisation, QR and FOD control for aeronautics.

- Green Seal: recyclable materials, clean processes, and verifiable certifications.

- One single partner: design, prototype, and series production from the same plant in Zaragoza, with competitive lead times throughout the peninsula.

Take the next step towards sustainability

If you are looking to protect your equipment with technical precision while driving your commitment to sustainability, at ZFoam we are ready to help you.

Contact our specialist technical team now and discover how we can create the sustainable future of technical packaging together.

Because at ZFoam, we passionately believe that true innovation always protects what matters most… your equipment and our planet.