Have you ever thought about what formats technical foams are manufactured in and what processes they undergo until you see the final product?

The most common foam formats are manufactured in blocks – foam sheets or rolls. From these initial formats at ZFoam, we carry out a complete transformation process up to the final product.

Initial transformation process or semi-conversion

This process starts by adjusting the thickness of the foams by means of:

-

Slicing

This consists of cutting blocks or sheets of foam into thinner thicknesses than the starting thickness. This method produces foam sheets or rolls with exact and uniform dimensions, which is essential for applications requiring tight tolerances.

The advantages of slicing include:

- Thickness accuracy: It allows you to obtain sheets with specific thicknesses, crucial for applications requiring tight tolerances.

- Waste reduction: By cutting precisely, material waste is minimised, optimising foam utilisation.

- Design flexibility: Different foam thicknesses can be produced to customer requirements, facilitating product customisation.

- Ease of handling: The resulting sheets are lighter and easier to handle, simplifying transport and installation.

- Lamination:

In contrast to slicing, it may be the case that the final product requires a greater thickness than the starting raw material. To overcome this circumstance, several layers are laminated (bonded) in order to achieve the required thickness.

Depending on the type of materials and thickness required, this lamination can be done by heat (thermal lamination), by means of glues – self-adhesives or by means of hot-melt substrates that melt at specific temperatures.

Subsequently, if the final product requires it, our sliced or laminated foams can be bonded with different types of materials, creating:

Sandwich materials

We can laminate self-adhesives, films of all types, raffia, cardboard and various substrates. This process allows us to improve the properties and functionality of the foams, adapting them to specific applications.

- Self-adhesives: Ideal for applications requiring easy installation, such as acoustic panels.

- Films: Provide a barrier against moisture and dust, used in electronic packaging.

- Raffias: Add strength and durability, useful in agricultural packaging applications.

- Cartons: Offer rigidity and structure, perfect for protective packaging.

- Miscellaneous substrates: Tailor foams to specific needs.

The advantages of sandwich materials are:

- Improved properties: Lamination can improve the mechanical and physical properties of the foam, such as impact resistance, durability and thermal insulation.

- Versatility in applications: It allows the creation of products that combine different characteristics, such as textures and densities, adapting to various industrial applications.

- Aesthetic customisation: Lamination allows the incorporation of different finishes, textures and colours, improving the aesthetics of the final product.

Once the semi-transformation process is finished, we proceed to the final transformation.

Final transformation

This process ensures precision and efficiency, guaranteeing that each piece of foam meets the highest quality standards

We use the process of cutting, die-cutting, machining and marking, etc., to obtain a final part that perfectly meets the needs of our customers.

Foam cutting

Cutting is one of the most common processes in the final transformation of foams. We use techniques such as automatic cutting with CNC (Computer Numerical Control) machines to adapt to the specific needs of precision and complexity.

Die cutting

Die cutting uses dies or punches to cut specific shapes into the foams. This method is ideal for mass production of identical parts, allowing precise and repeatable results.

For example, at ZFoam we use die cutting to manufacture automotive components.

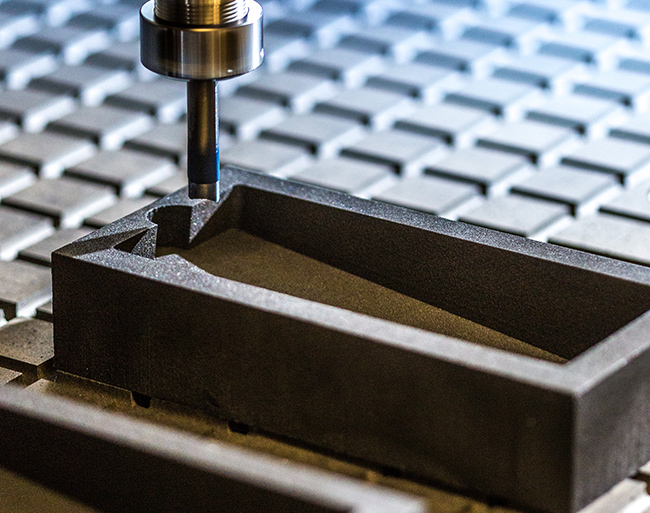

Machining

Machining involves the use of rotary tools to create complex shapes in foams by machining.

At ZFoam, we apply machining for foam parts used in industrial and packaging applications, where tight tolerances are required.

Marking

Marking allows information, logos or instructions to be printed directly onto the foam surface using techniques such as hot stamping or laser marking. It is essential for packaging and signage applications.

ZFoam sheets

At ZFoam, we pride ourselves on offering a complete range of foam sheets and rolls that meet the highest demands for quality and sustainability.

Whether you need cross-linked, non-cross-linked, eco-friendly, cellular rubber, or other foams, we have the ideal solution for your project.

In addition, our extensive converting capabilities ensure that every piece of foam is perfectly tailored to your needs.

We invite you to download our complete catalogue to explore all available options and find the perfect solution for your needs.

Visit our foams website for more information and to download the catalogue