Non-reticulated PE foams

Gas-expanded non-reticulated polyethylene foams.

These foams are widely used as packaging and coating materials and in the manufacture of products for the food industry, owing to their great flexibility, impact and vibration resistance, anti-static properties and ease of use. They can also be used for acoustic and thermal insulation and are 100% recyclable.

Presentation formats for non-reticulated polyethylene foam:

- Sheets

- Spools

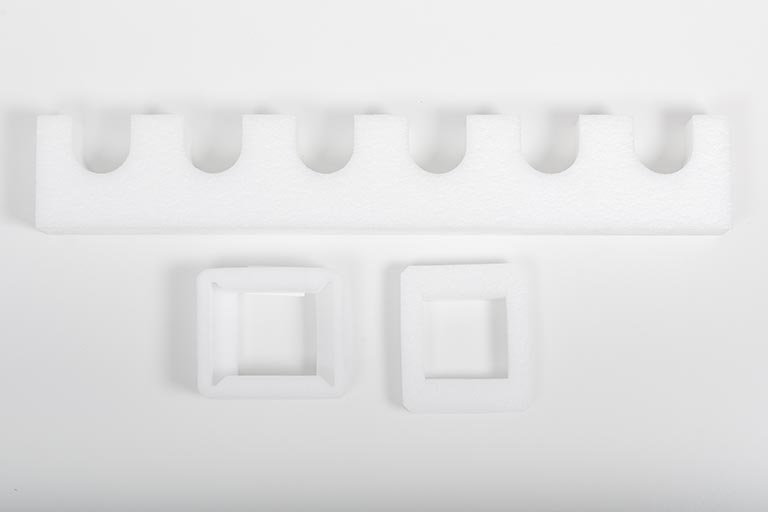

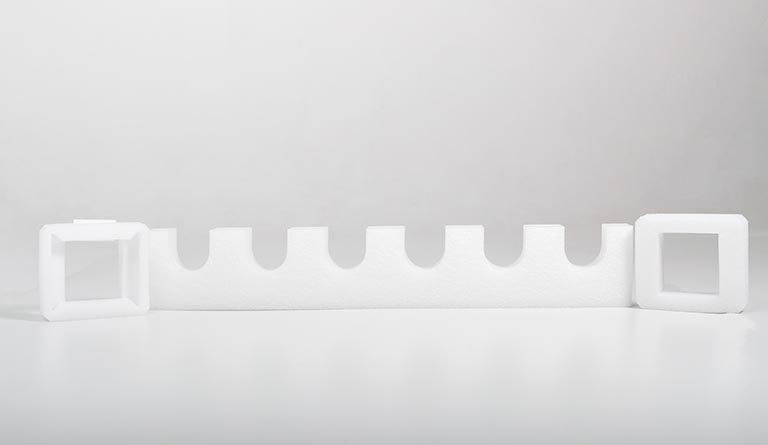

- Finished items

NON-RETICULATED PE FOAMS FOR:

Automotive industry

Rail industry

White goods

Electronics

Healthcare industry

Suitcases

Artworks

Sample cases

Logistics

Isothermal containers

Electronics

Swimming pools

Body Board

Archery

Building

Non-reticulated polyethylene (PE)

At ZFoam we work with this raw material extensively, using different types of semi-conversion (splitting, lamination, butt-welding, adhesive coating and substrate lamination, among others) and conversion processes (routing, machining, water jet cutting, CNC cutting, die-cutting, thermoforming, tape, and digital and laser printing) to produce a wide range of products that are used in many different sectors – such as the food and cosmetics industries – that have very different needs and requirements.

Characteristics of non-reticulated polyethylene foams

Non-reticulated PE foams are characterised by their closed cells and are expanded using gas to produce densities ranging from 20 to 150 kg/m³.