RUBBER FOAMS

Technical foam based on EPDM, CR, nitrile with closed or semi-closed cell structure

Like reticulated and non-reticulated PE foams, rubber foams offer excellent levels of insulation and impact protection. They also stand out for their high levels of resistance to weathering, ozone, ultraviolet light, abrasion and chemical agents, and their capacity to withstand temperatures ranging from -40 to 140°C, which makes them an extremely durable and long-lasting option.

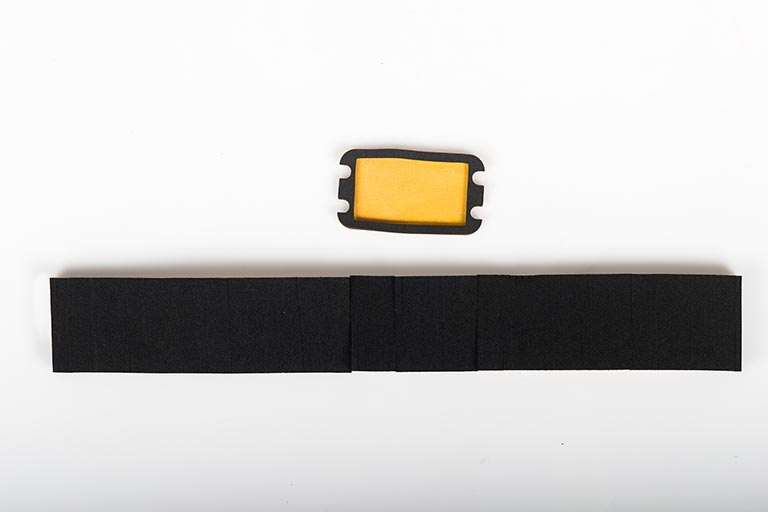

Presentation formats for technical rubber foams:

- Sheets

- Spools

- Finished items

RUBBER FOAMS FOR:

Automotive industry

Rail industry

White goods

Aeronautical

Renewable energies

Building

Logistics

Rubber foams with or without adhesive

These foams may or may not include adhesive coating and are soft in appearance, with properties that make them ideal for sectors such as the automotive, rail and construction industries. They are also used in the manufacture of products such as orthopaedic aids, hoses, gaskets, seals, tape, profiles, and many more.

Rubber foams: density and base

We work with rubber foams based on EPDM (ethylene propylene diene monomer), CR (chloroprene) and nitrile, with both a closed and semi-closed cell structure and densities starting from 70 kg/m³.