Until now, we have seen what the Life Cycle Analysis Calculator that we have developed together with the Circe Foundation is, and what are the input values that it needs to provide real and objective data on the environmental impact that we generate. Information that we share in a transparent manner with all our clients.

Today we want to show you how the calculator works with a real practical case and the differences we find between the use of different types of foam and other materials, such as cardboard.

This is how our LCA calculator works

We start with a challenge and some keys, which serve as guiding thread in this practical case.

Challenge:

Demonstrate with data that the use of technical foams can have a lower environmental impact than the use of materials such as cardboard.

Keys:

The LCA calculator is very useful showing that use of foams such LD18 or LJ45 BIO offers, in some aspects, a lower environmental impact than other traditional materials.

Input data

We take some input data (raw materials, water and electricity consumption, final packaging, distance to the customer and waste).

All the values are provided by ZFoam, except for shipping distance (provided by the client) and the waste generated, which we assume will be correctly sorted and recycled.

We take as a model a piece of cardboard that is quite common in the world of cosmetics, which includes different gift products and we compare it with the different types of ZFoam foams.

The results at a glance

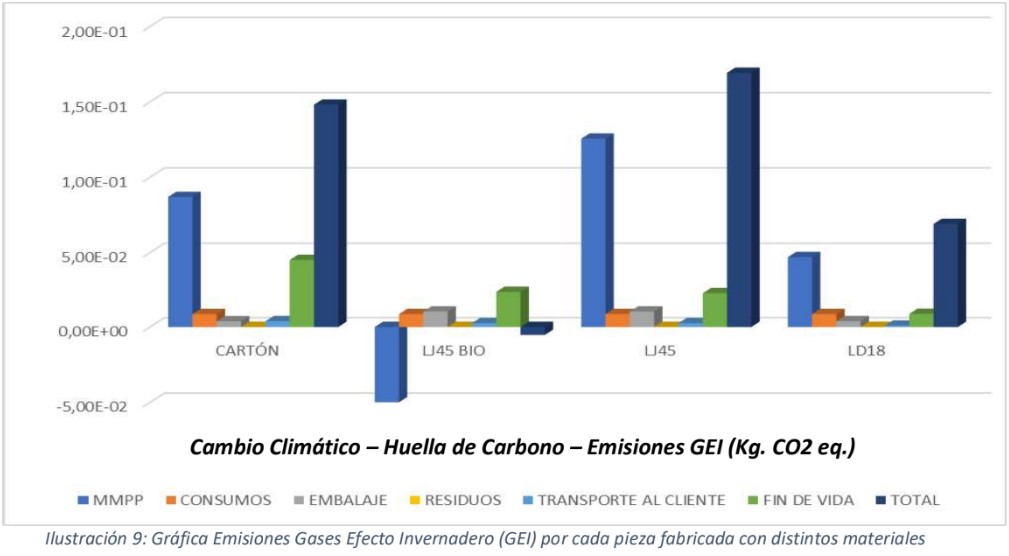

Greenhouse Gas Emissions – Carbon Footprint:

The graph speaks for itself, highlighting how LJ45 BIO foam has a negative carbon footprint compared to any other material used.It has as well as very low rate of consumption or waste. Without any doubt, it makes an important difference to take into account.

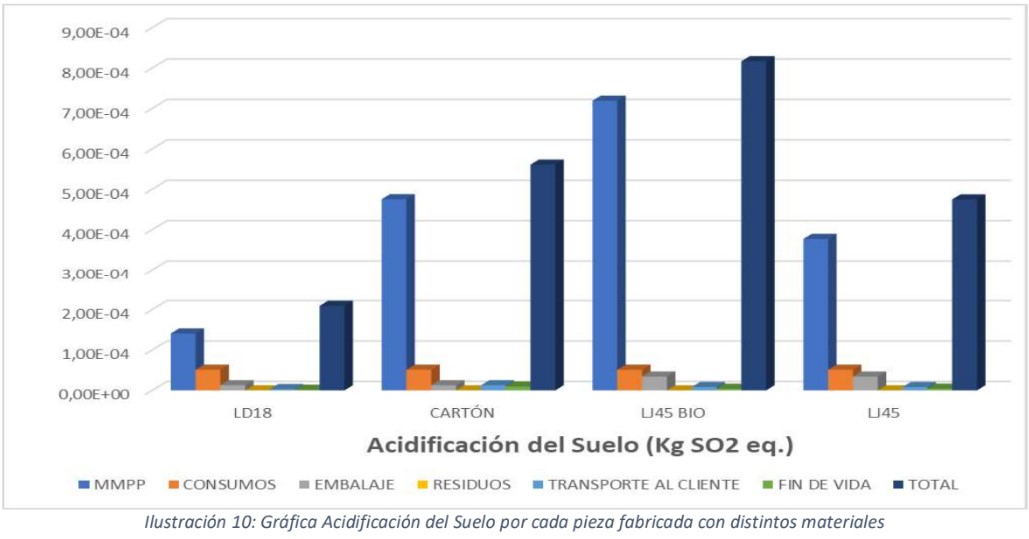

Soil Acidification:

This is a clear advantage in terms of environmental impact of some types of foam compared to cardboard. . Thus, in terms of soil acidification, LD18 foam is shown as the material with the least impact, followed by LJ45 foam.

An exception must be made regarding LJ45 BIO foam and the high values it shows. This is due to the fact that it is a material made from sugar cane: soil acidification is inevitably greater than in other cases, although, let us not forget that it is the only material that we have analyzed with a negative carbon footprint.

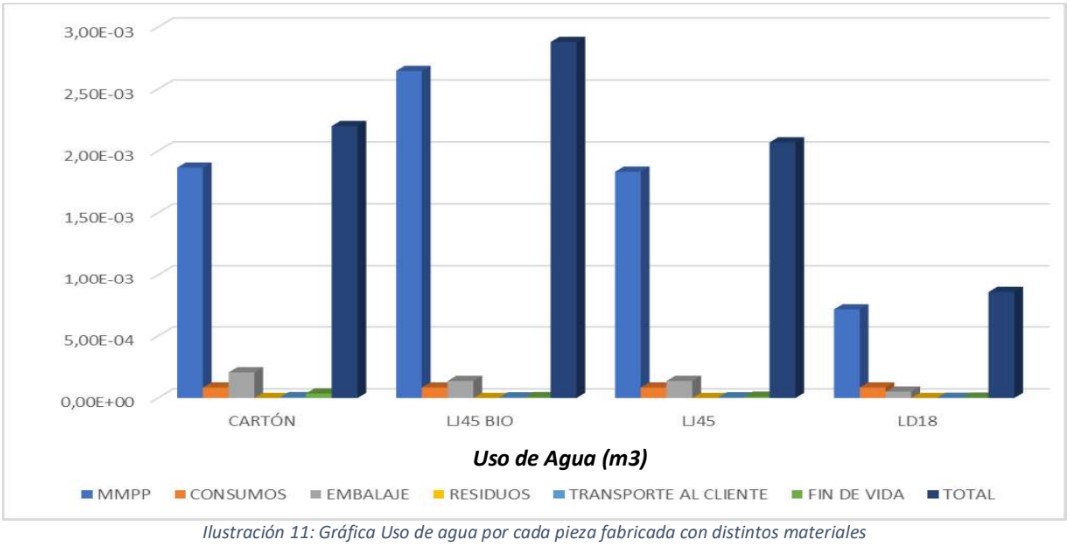

Water use:

If we take into account the water use, LD18 foam has a considerable advantage over other materials, since we are talking about an extremely light foam with a very low environmental impact. On the other hand, LJ45 foam, without offering values as low as LD18, also has better results than cardboard.

Conclusions

Through the Life Cycle Analysis Calculator, we clearly see how a material as cardboard does not have to be the most suitable in all cases.

In fact, we have verified with real data, verifiable and calculated based on current regulations, that using foams such as LJ45 BIO or LD18, it is possible to make packaging that is more environmentally friendly, more sustainable, of great quality and that it also offers very wide customization possibilities.

Links to the Life Cycle Assessment Calculator article series:

- https://www.zfoam.com/analisis-de-ciclo-de-vida-de-nuestras-espumas-que-es-y-por-que-lo-calculamos/

- https://www.zfoam.com/acv-analisis-de-ciclo-de-vida-datos-de-entrada-y-resultados-de-salida/

- https://www.zfoam.com/impactos-ambientales-calculadora-acv/

- https://www.zfoam.com/calculadora-acv-zfoam-te-mostramos-como-funciona/