You already know about the efforts that ZFoam have long been making in order to use sustainable, recycled and recyclable foams, contributing to care for the environment and to the transition towards the circular economy. But this labour would not be complete without also focusing them on improving the foam recycling process, where progress is now possible with chemical recycling.

What is the chemical recycling of foam? How does it differ from mechanical recycling and what advantages does it offer? We explain this to you in this article using polyethylene foams as a reference.

It all begins with polyolefins

Polyolefins are synthetic resins that are prepared by polymerising monomers (ethylene) using hydrogen and carbon. The most widely known polyolefins are polyethylene and polypropylene.

Although we work with many different types of foams at ZFoam, most are composed of polyolefins. In fact, polyethylene, a simple polymer with a structural formula of (-CH2-CH2-)n, is one of the best-known thermoplastics on the market. It is typically used for very diverse applications, including packaging, healthcare, sports equipment, footwear and tool protection, and in such sectors as rail, automotive, food and construction, to name a few.

This is because polyethylene is very easy to process and has great resilience, ductility, excellent chemical resistance, low permeability to steam and very low moisture absorbance.

Why is the difference between mechanical and chemical recycling so important?

Despite the different classifications of foams according to density, we mostly have low-density polyethylene (LDPE) foams and, to a lesser degree, high-density polyethylene (HDPE) foams.

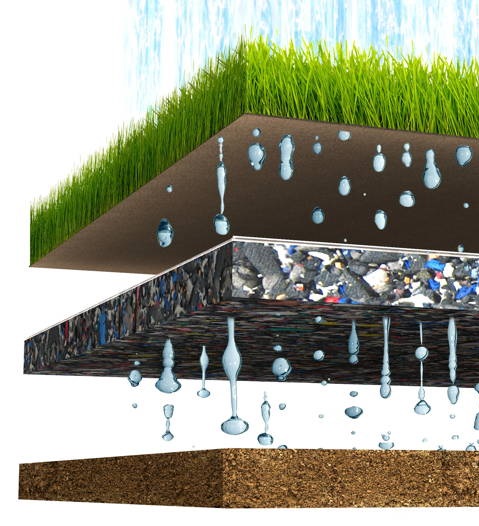

Both types of PE foam are 100% recyclable via a mechanical process (they undergo a grinding and subsequent agglomeration), which is the treatment we have spent years applying to the scraps and off-cuts from our manufacturing, from which we make an elastic sub-base for artificial turn for sports and recreational facilities.

Chemical recycling, on the other hand, allows the foam to return to its initial state (the original monomer) and return to the manufacturing process for new products of all types.

More about the chemical recycling of foams

Specifically, chemical recycling is based on processes such as pyrolysis (thermal decomposition in the absence of oxygen), gasification, hydrogenation and cracking.

In recent years, chemical recycling processes via the pyrolysis of polyethylene have advanced to the point where it is today possible to breakdown polyethylene polymers in reactors of different sizes to obtain different compounds and fulfilling the concept of circular economy advocated by ZFoam.

This is because we can obtain the initial monomer, which can once again undergo the polymer manufacturing process, whether polyethylene or other ethylene-based plastics. The result is a 100% recycled product, which is also able to be recycled in the future.

However, chemical recycling offers even more important advantages, such as:

- Possibility for mixed and contaminated polymers to undergo a simple pre-treatment process that does away with complicated separating required for mechanical recycling.

- Lower energy costs and water use in the chemical recycling of polyethylene, even lower than those required by paper and cardboard recycling, ensuring sustainable use of resources.

At ZFoam, we are very satisfied with the chemical recycling of foams, because together with the use of environmentally friendly materials, such as our range of ECO & BIO foams, we are coming closer to a circular economy that is better for industry, people and the planet.