The manufacture of foam packaging solutions is one of our strengths. This is due to the excellent value we offer professionals in any sector who require efficient foam solutions to protect and display parapharmacy and cosmetic products, and for daily use in laboratories, among many others.

This value is instantly patent in the high quality of the foams, as well as their flexibility to adapt to any design, and because of the low environmental impact of their manufacturing process, particularly when using our range of ECO foams.

If you belong to any of the sectors mentioned, keep reading because you’re sure to find the perfect solution for your needs.

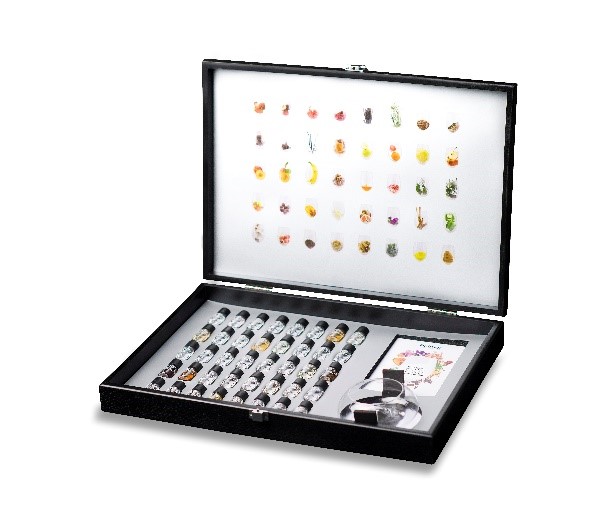

Customising foams for cosmetic and parapharmacy products

We know the importance of good design and a meticulous presentation have in the sector, in addition to proper protection against possible impacts. This is why we offer a wide range of foams which, in addition to these properties, are odourless, pure and free of chemical foaming residues, so as not to alter the properties of the articles they are used with.

Speaking of design and presentation, it might interest you to know that we can customise the foams to suit each article by means of:

- Surface finishes and textures

- Wide range of colours

- Cardboard and textile lamination

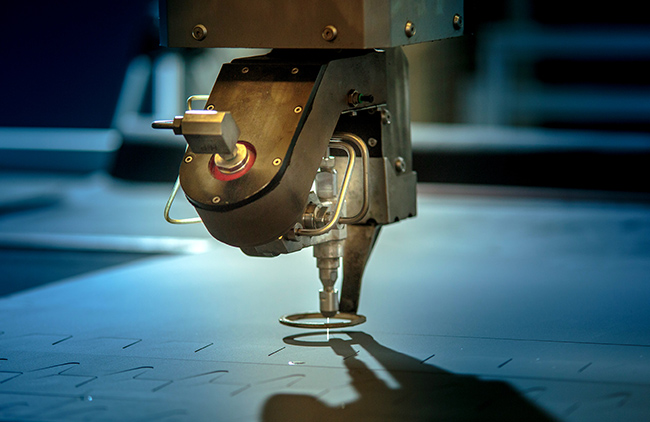

- Laser cutting

- Digital printing

You need only contact us to find out about all the options available to you and choose the best one to suit your needs. If you are unsure of your needs, let us advise you.

ZFoam transformation of technical foams

As manufacturers of foams with over 30 years’ experience, our modern equipment can deal with all the specialised transformation processes for plastic foams, including:

- 2D and 3D water jet cutting systems

- CNC cutting and punching

- Thermoforming

- 2D and 3·D mechanisation

- Gluing

Thanks to the high quality of our foams, the wide variety of materials for different uses and sectors, and the possibility of customisation, finding the solution to suit your needs will be a very simple process. Besides, we will also guide you throughout the process to clear up any doubts that may occur to you.

Our team will provide the technical support you need: from the choice of raw material, via the most suitable design and transformation process in each case, to the final product.

Finally, we would like to point out that foams are actually more environmentally friendly and sustainable than other materials in daily use. This is because all foams are recyclable, and because they have a very low density, smaller quantities of raw materials and shorter production times are required, resulting in a lower environmental impact and higher energy savings.