At ZFoam we are part of ever-increasing progress in the use of sustainable materials for a wide variety of solutions in the packaging sector. Therefore, we are delighted to present our new, completely recyclable product for isothermal solutions, which is in the same channels as paper and cardboard. It has a minimal carbon footprint, all while retaining its properties as a thermal insulator..

ZPack Isotherm

This product comprises an inner lining for cardboard boxes made of a cellulose-based foam insulating material, which is also an excellent thermal insulator.

Its great advantage is in offering a viable alternative to other insulating materials, such as EPS (expanded polystyrene) or PU (polyurethane) plastic foams, which require a more complex and specific recycling process.

The characteristics of this cellulose-based foam insulation mean that:

- It is ideal for refrigerated or frozen products.

- The box and its insulation are fully recyclable through the cardboard and paper channel

- It features excellent thermal insulation (λ = 0.036 W/mK).

- It is lightweight and easy to use (insulation 30 kg/m3 density).

- It can adapt to any type of cardboard box, from the smallest through to pallet boxes or any other dimension as required (contact us for more information)

- It has a capacity to absorb shocks.

- It enables an extended lead time for products delivered via unrefrigerated vehicles.

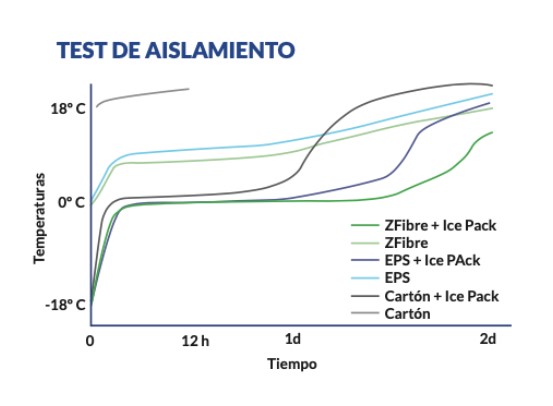

This foam can form part of the base, the lid, or the sides of the box. It can cover the whole of the inside of the box where necessary. The following graph shows its performance as a thermal insulator:

Furthermore, this foam is manufactured using dry forming, which is an environmentally-friendly process that is low on energy consumption and uses no water.

We are expanding our range of recyclable and sustainable products

A new range of products that have set us on the path to a circular economy and sustainability at ZFoam are now available, in addition to the new fully recyclable isothermal boxes in the paper and cardboard channels (already on the market).

The highlights among them are the ECO foams, which range from fully recyclable (such as the ECO S33), to those from 100% renewable raw materials obtained from sugar cane, forest residues or used cooking oils, complete with a negative carbon footprint (e.g., our LJ BIO, BIO PT and BIO PN foams).

In addition, mention must be made of the recycling of all the waste we generate (including cutouts and leftover foam inserts) – a process that is ongoing since 2016 – as well as the development of a Life Cycle Analysis calculator (LCA). This enables our clients to have detailed, objective information about the environmental impact of manufacturing their products.

We also have a Gold Medal awarded by Ecovadis for our sustainable practices, plus the International Sustainability & Carbon Certification (ISCC), which ensures the traceability of the materials that go into our BIO foams.

We are currently engaged in attaining the ZFoam Zero Waste certificate and in the development of chemical foam recycling, among other measures, more about which to come.

Insulators from cellulose-based foam

Consequently, we see the launch of cellulose-based foam insulation as a logical and exciting step towards the use of increasingly cleaner, easily recyclable and environmentally-friendly products.

If you want to know more about the new 100% recyclable Isotherm ZPack, get in touch! We would be delighted to provide you with all the information you need.