Since 1992, at ZFoam we have specialised in the transformation of technical foams and insulation for sectors where precision and reliability are essential, such as the automotive industry, defence, high-end packaging and industry in general.

Our market leadership is based on the know-how accumulated over more than 30 years and on constant technological investment, which gives us the largest CNC cutting capacity in the Iberian Peninsula

This productive strength is based on a combination of different techniques (waterjet, CNC and die cutting), which allows us to guarantee fast delivery, unbeatable flexibility and the ability to handle large production runs with ease.

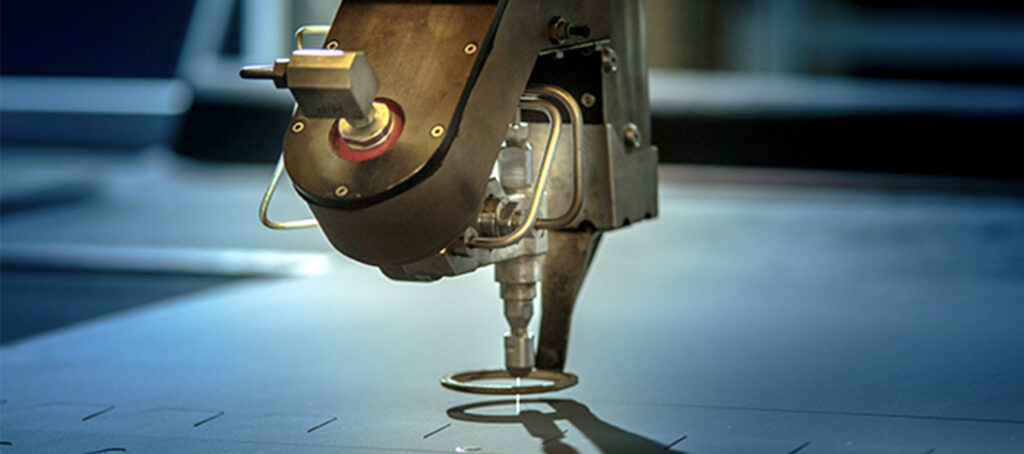

Waterjet cutting: fast and highly accurate cutting

Waterjet cutting is a cold cutting process. This is crucial because it uses a jet of pure water that does not generate heat, melt or deform the material, or produce toxic fumes or vapours.

This method is ideal for the precise and cost-effective cutting of soft materials such as foam, rubber or different types of insulation.

With our large installed capacity, we offer:

- Cost savings: Since foam is a soft material, the use of pure water jets without abrasives is recommended, which significantly reduces the total cost of cutting. In addition, this cutting technology avoids the use of moulds, dies and tools, making prototyping quick and economical.

- Precision and 3D cutting: Waterjet cutting produces clean, sharp cuts with a precision of up to 0.1 mm.. Los cabezales de Five-axis heads are essential for cutting bevels, cones and complex angles, fundamentally solving the problem of bevelling at the edges caused by three-axis machines.

- Massive volume and unlimited thickness: a jet of pure water can effortlessly cut thick foam with unmatched cutting quality.

CNC milling:

When a part requires blind holes, recesses, bevels or detailed housings, CNC milling comes into play. This process uses computer-controlled tools to machine by chip removal and achieve very tight tolerances.

Our machinery specialises in repeatability and consistent finishing for all types of series: prototypes, small, medium or large:

- Complex 3D geometries: CNC foam milling machines are ideal for creating complex shapes, 3D contours and detailed engravings that would be difficult to achieve with other technologies. We use flexible and precise CNC milling machines, which allow for the cutting, machining and milling of all types of parts.

Industrial die cutting: machinery for large series efficiently

Die cutting, which uses a cutting-edge instrument (die), is the best option for maximum efficiency and speed in the production of large volumes of flat, repetitive parts.

With a large installed capacity, we can manufacture thousands of identical parts with precision, offering you very competitive costs per part in long series.

ZFoam: multi-technology, quality and commitment

The combination of these three technologies, together with complementary processes and our work philosophy, results in:

Comprehensive service and precision

- Vertical integration: We offer a complete service ranging from the selection of the most suitable materials and conceptual design to manufacturing and delivery.

- Precision: ZFoam offers the full range of foam thicknesses with very tight tolerances.. This allows us to manufacture foam that exactly meets your needs, especially when the part goes at the bottom of a box.

- Complementary processes: Our capabilities include:

◦ Lamination: We combine foams with technical textiles (such as Kevlar® or Aramid) for improved ballistic, thermal and chemical resistance.

◦ Thermoforming: Thermal adaptation of foams to moulds to obtain three-dimensional solutions in a single piece, reducing extra assembly.

◦ Adhesive bonding: Precise application of double-sided adhesives so you can stick the piece to your box or suitcase by simply removing the protective paper.

◦ Laser marking: Direct laser engraving to include logos, text or coding.

Quality, Automotive and Sustainability

- IATF 16949 Quality: We are ISO 9001 and IATF 16949 certified.. IATF 16949 is a standard that consolidates us as strategic partners in the automotive industry, promoting continuous improvement, defect prevention and waste reduction.

- Sustainability as a Priority: Our commitment to sustainability and the circular economy is demonstrated by:

◦ ISO 14001 certification.

◦ Ecovadis Gold Medal recognition.

◦ Use of biomaterials (such as those derived from sugar cane, which have a negative carbon footprint) with traceability certified by ISCC PLUS.

◦ ZFoam ECO foams produced of up to 40% recycled material

Technology + experience = ZFoam solutions

Our combination of experience, capability and reliability makes us the industrial partner you need.

We offer you the technological capability to optimise your projects, ensuring precision, certified quality (IATF 16949) and Industry 4.0 agility.

Do you need a technical foam solution with delivery times that meet your industrial demand?

Contact our technical team for comprehensive advice, from design to the final product.